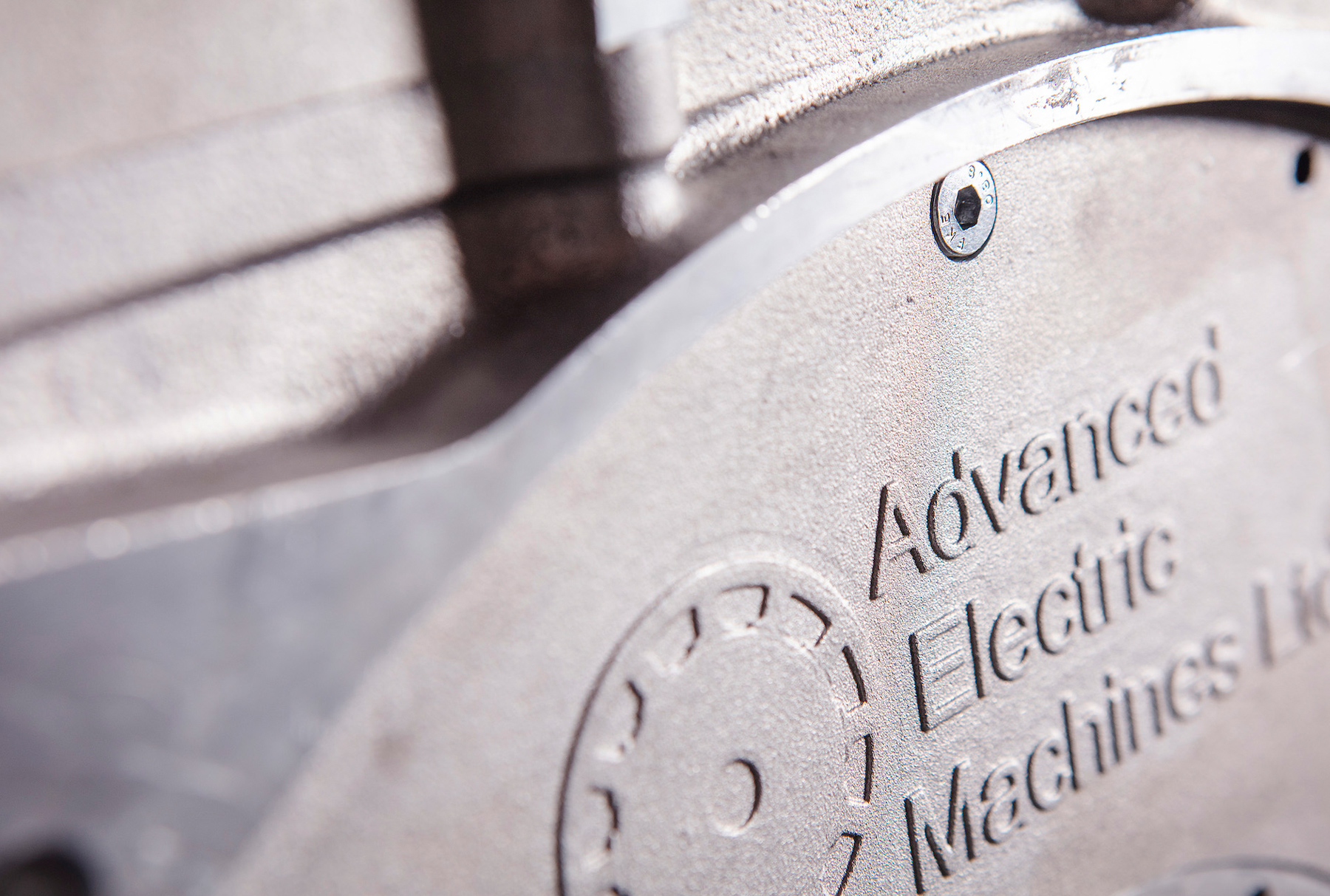

Advanced Electric Machines

Advanced Electric Machines (AEM) Group is driving change in the electric car industry.

Innovative, high-performance traction motors

To meet greenhouse gas targets, 60% of new cars in the UK will need to be low-emission models by 2030. Electrification is gaining momentum in the automotive sector. While this is helping to lower carbon levels, the majority of electric motors rely on unsustainable rare earth elements. They need materials, such as copper, that are difficult to recycle when assembled in an electric motor.

That’s the great thing about working with the University – we get to anticipate future problems and work towards solving those issues now.

AEM Group is addressing these challenges head on. They are leading the way in developing a new generation of recyclable, lightweight and energy-efficient motors. The motors can be produced in high volumes and at low cost. They also cut the need for these problematic materials.

The company, which was spun out of Newcastle University in March 2017 by alumni Dr James Widmer and Dr Andy Steven. They have since secured investment to manufacture up to 12,000 traction motors per year.

Gearing up for the future

James joined the University from industry in 2010 to complete a PhD. He oversaw the School of Engineering’s research into Advanced Electric Drives. The team played a crucial role in delivering new technology. They helped companies like Jaguar Land Rover to build its first electric vehicle and Airbus to achieve the world’s longest ever flight using an electric motor.

The University’s pioneering work in this field led to becoming the Electric Machines Spoke for the Advanced Propulsion Centre (APC). The APC is the funding body for low-carbon vehicle research in the UK. James was appointed as the director. He led policy development to future-proof car manufacturing in the UK. That was when he spotted a gap in the market for a more sustainable alternative to traditional electric motors.

Continued collaboration

Today AEM Group produces traction motors for electric trucks. They are also scaling up production to develop advanced technologies for clients such as Bentley and Airbus. The company has strong ties with the University. James continues to work for the School of Engineering one day a week.

“With the drive and momentum towards more vehicles requiring electric motors, we have to make sure there are enough companies out there that can make parts, and that enough people are trained in these areas,” explains James. “That’s the great thing about working with the University – we get to anticipate future problems and work towards solving those issues now.”

AEM Group has been instrumental in securing £80 million worth of investment from the government’s Industrial Strategy Challenge Fund, known as ‘Driving the Electric Revolution’. Together, the company and the University are hoping to use the funding to secure the North East of England’s position as the UK’s leading centre of electric drivetrain research and manufacturing.

“It’s fantastic to have spun out from the University because of the brilliant research that is still going on,” adds James. “Looking to the future, we want to continue working in partnership with the University and also hope to recruit people who’ve been trained there.”