Research Theme: Machines

We lead the way in research in electrical machine design.

We have a long history of pioneering academic and industrially driven research.

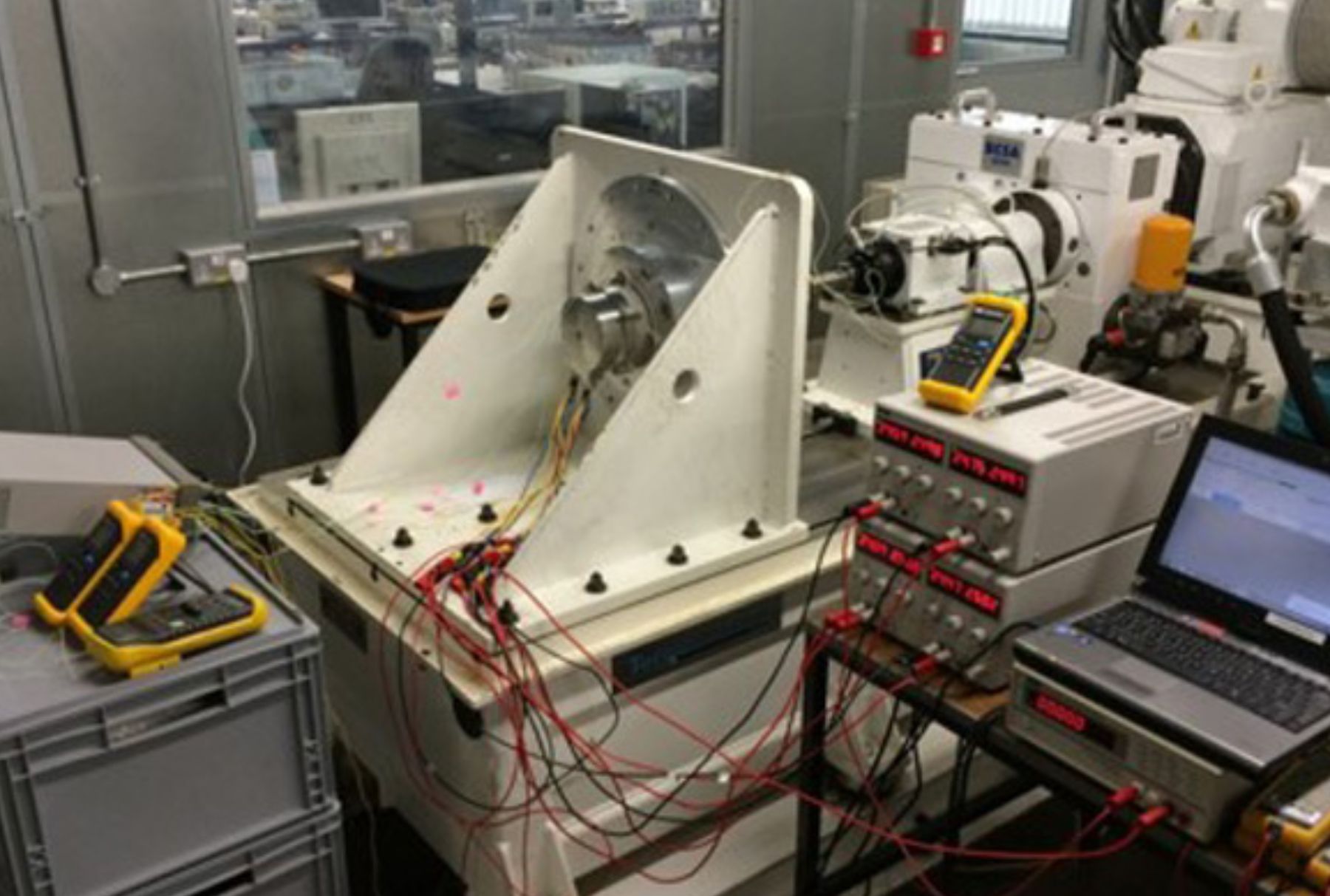

We work on the full spectrum of machine topologies. These include permanent magnet, reluctance, transverse flux, linear, high speed and axial machines. We have a track record in demonstrating power dense, fault tolerant machines built and tested in house.

We have worked with many industrial partners to drive down the manufacturing cost of motors produced on an industrial scale. We do this by improving efficiency and reducing material mass. We also devise winding techniques that are production line friendly.

Linear machines

- Wang J, Baker NJ. (2018) A Linear Laminated Cylindrical Transverse Flux Machine for use with a Free Piston Engine. IEEE Transactions on Energy Conversion 33(4) pp1988-1997. https://doi.org/10.1109/TEC.2018.2877502

- Baker NJ, Raihan MA, Almoraya A. (2018) A Cylindrical Linear Permanent Magnet Vernier Hybrid Machine for Wave Energy. IEEE Transactions on Energy Conversion https://doi.org/10.1109/TEC.2018.2879405

Contact

Soft magnetic composites

Soft Magnetic Composite (or SMC) is a material consisting of individually insulated iron particles. They can be pressed together to form components. These components are capable of transmitting and suppressing flux in three dimensions. In this way, it is possible to build machines that have a 3D flux path.

As the particles are so small, SMC is a material known for its low iron losses, especially at high electrical frequencies.

We are the only UK university to work directly with suppliers of Soft Magnetic Composites, as we have done for almost 20 years. We have demonstrated SMC machines belonging to transverse flux, axial and linear machine topologies.

For example, the Yokeless and Segmented Armature – the YASA machine – is easily fabricated from SMC. The soft magnetic composite material carries the flux in its non-planar path. It does this without incurring excessive losses. It does not need an impractical lamination design that is difficult to manufacture. We have done work on the design, build and thermal aspects of the YASA machine.

Contact

Switched reluctance

As part of our strive towards low cost machines, we have worked with a variety of switched and synchronous reluctance topologies. These machines have the potential to offer low or zero magnet machines with inherent fault tolerance.

We are working on segmented and more conventional machines within both the aerospace and automotive sectors. Their performance rivals that of the more common permanent magnet topologies.

Contact

Novel topologies

Over the last three decades, we have analysed, designed and tested many new electrical machine topologies. These all satisfy industrial need: axial, double rotor, transverse flux and modular pole machines.

See for example:

- Baker NJ, Jordan S. (2018) Comparison of Two Transverse Flux Machines for an Aerospace Application. IEEE Transactions on Industry Applications 54(6) pp5783-5790. https://doi.org/10.1109/TIA.2018.2849737

Contact

Halbach arrays

Using Halbach arrays instead of conventionally magnetised magnets offers the potential of a reduced coreback. Hence, they can provide higher torque density in some applications.

Demagnetisation, physical air-gap and torque capability at both continuous and overload operation are all affected. In one fixed volume application, we found that using one transition per pole increased rated torque by 5% and overload torque by 3%. Using three transitions per pole, we found that this topology gives an increase in the overload torque of 4%.

We are presently investigating a novel trapezoidal Halbach array arrangement. This will reduce the demagnetisation of the transition magnets. It will also increase their permeance coefficient.

- Contact: Dr Nick Baker

EPSRC Future Electrical Machines Manufacturing Hub

The Electrical Power group is a partner in the EPSRC Future Electrical Machines Manufacturing Hub which combines expertise in electrical machines and manufacturing for the first time. This £28m investment will enable researchers at the new EPSRC Future Electrical Machines Manufacturing Hub to work with industry on addressing key manufacturing challenges.

Together with key industrial partners including Höganäs AB, Dyson, Rolls Royce and McLaren, the hub will lead on the design of new electrical machines with improved performance for the aerospace, energy, automotive and premium consumer sectors.

Through delivering world-class manufacturing research and innovation, the Hub will assist UK manufacturing to capture significant value in the electrical machine supply chain, improve UK industrial productivity and deliver the environmental benefits and cleaner growth at the heart of the UK’s industrial strategy.

At Newcastle we are focussing on the manufacturing of modular machines and their thermal management which has the potential to significantly increase power densities to meet the future targets of aerospace and automotive applications.