George Hall

Investigating porosity in alloys for maxillofacial and musculoskeletal implants.

Email: g.hall4@ncl.ac.uk

Project supervisors

- Professor Kenneth Dalgarno

- Dr Hemantha Yeddu

- Dr Javier Munguia Valenzuela

Project description

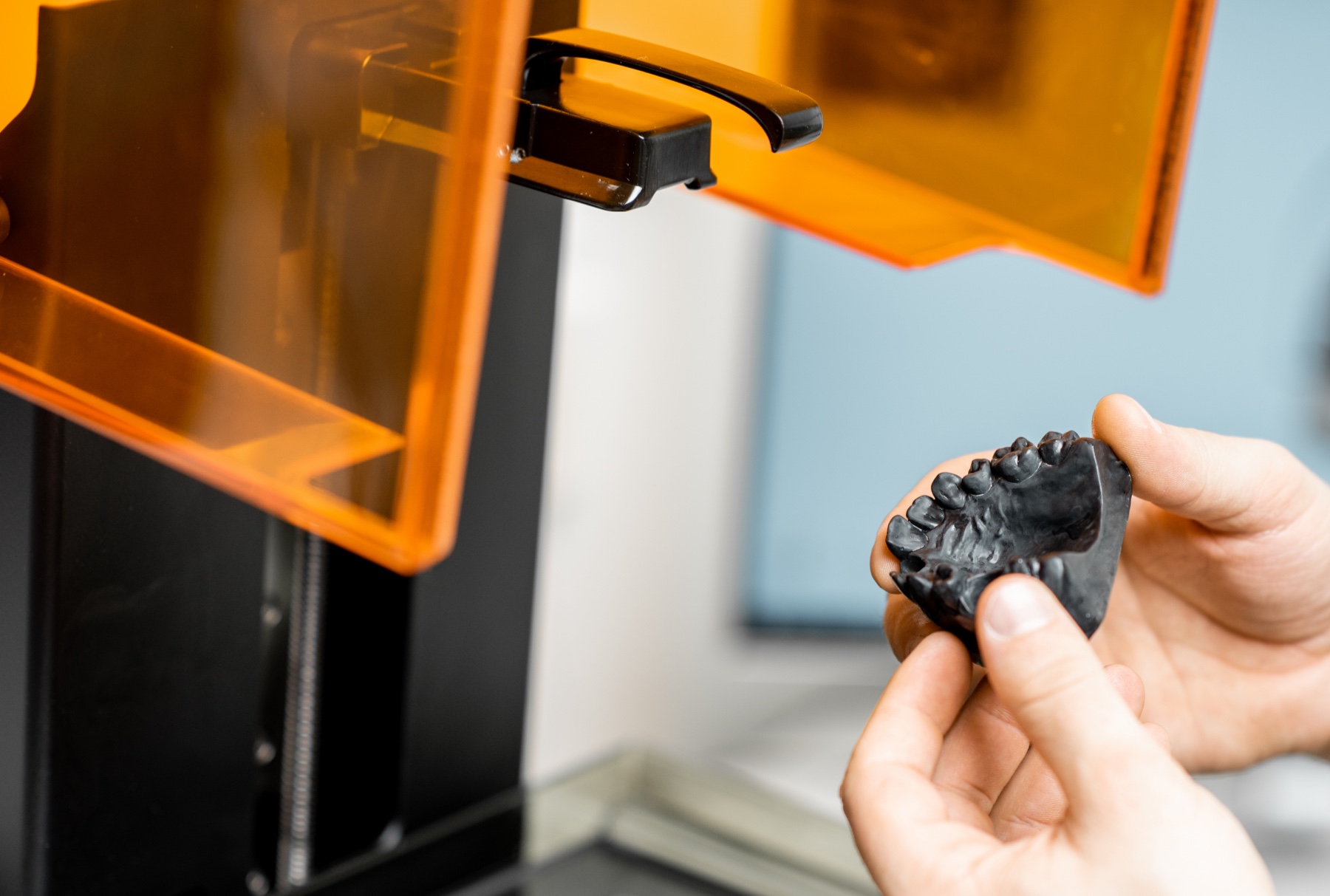

Powder bed fusion is a set of additive manufacturing (AM) techniques. It uses a high powered laser or stream of electrons to fuse the layers of powder together. The method allows for an almost 100% dense product with complex geometry. The specific technique used in this project is Electron Beam Melting (EBM). This uses a stream of electrons focused through a series of lenses to fuse powder together. The high speed electrons convert kinetic energy into thermal energy which causes the powder to melt.

Ti-6Al-4V is a commonly used high specification metal alloy. It has high specific strength, corrosion resistance and good biocompatibility. This alloy is in high demand in the medical industry, for maxillofacial and musculoskeletal implants. In these applications, the need to withstand repeated loading is essential for product function.

Fatigue strength is detrimentally affected by porosity within products. I will analyse variables in the Electron Beam Melting powder bed additive manufacture process. I will relate these to porosity. I will increase our knowledge of the sources of porosity for implementation within a quality system to avoid the formation of porosity. This will allow manufacture of repeatable properties from batch to batch. It will establish a standardised process for high performance functional implants.

Qualifications

Masters In Design Engineering