Mechanical Workshop

The Mechanical Workshop is engaged in the design and manufacture of research prototypes to individual specifications.

Overview

We use a range of materials including modern plastics, stainless steels, aluminium, brass and precious metals.

The Mechanical Workshop is fitted with a large range of machines and equipment.

We also offer a consultancy and advice and provide assistance in the design, manufacture and repair of any mechanical component.

Working closely with the Electronic and Glassblowing workshops, we provide a comprehensive technical service.

In recent years our projects have been varied, including:

- servicing of vacuum pumps of any type

- hot plate stirrer sample holders

- design and fitting of pressure and vacuum systems

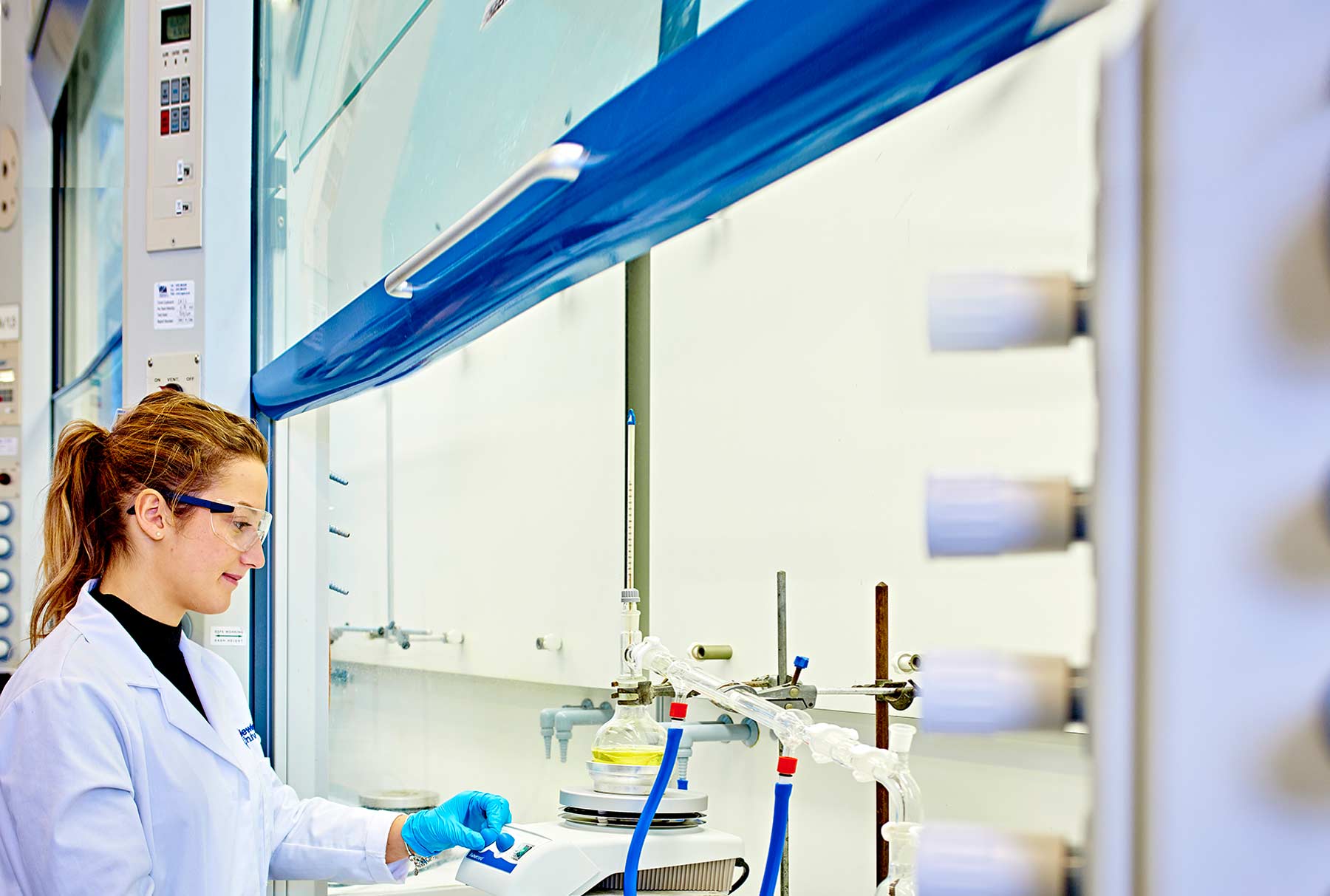

- fitting of aluminium scaffolding into fume cupboards

We've also manufactured:

- cells for Nanochem from PTFE plastics

- opticall cells

- sample holder trays for Schlenk tubes

- waste solvent extraction hoods

Our services

System/pump servicing and repair

We are able to service most vacuum pump types from rotary oil vane, diaphragm and scroll. We provide a service from simple oil changes and testing, with precision measuring gauges, to full overhauls. Vacuum pumps are expensive pieces of equipment, so it is worth investing in a service.

The Mechanical Workshop can also repair faulty motor bearings and supply all the necessary fittings to build a vacuum system to your own requirements.

In addition we can repair/service rotary evaporators and other equipment.

Rotary Oil Pumps (high vacuum)

Rotary Oil Pumps are often used on Schlenk lines and freeze dryers. With our expertise in this area we recommend an oil change and flush, with gas ballast at least every three months.

You can arrange a regular service with us to keep your equipment in good working order.

If you notice any contamination at all in the sight glass of your pump, just arrange to bring the pump to the workshop as soon as is practical. The longer you leave a pump running with solvents etc in the oil the more chance you have of damaging the pump permanently. Service kits and spare parts are available and we can get these at favourable rates if disaster ever strikes.

Maintenance tips

Every day we recommend running your vacuum pump on gas balllast for 30 minutes before you start your chemistry and after you’ve finished for the day. Close the vacuum connection to your line or equipment and open the valve marked gas ballast. This purges the pump of contaminates and keeps the pump in good condition for longer.

If you think there is any kind of problem at all, from oil leaks to strange smells or noises emitting from the pump contact the workshop immediately and we'll find a solution.

Manual handling

For all manual handling issues in the School of Chemistry, movement of heavy/large objects over 25kg just contact us.

Staff

Gary Day

Email: gary.day@ncl.ac.uk

John Corner

Email: john.corner@ncl.ac.uk

Contact us

Find out how to contact us.

The School of Chemistry's Mechanical Workshop is located on the basement floor of the Bedson Building.

Mechanical Workshop

School of Natural and Environmental Sciences

Bedson Building

Newcastle University

Newcastle upon Tyne

NE1 7RU

Tel: +44 (0) 191 208 7064Email: chem-mech.workshop@ncl.ac.uk